If you are picturing a compact home lift, the first question is almost always about space. How small can you go without sacrificing comfort, safety, or the look of your home? The short answer: a lot less than you might think. The long answer is where the right planning pays off.

The aim here is to translate technical requirements into something you can measure on your plans or mark out on a floor.

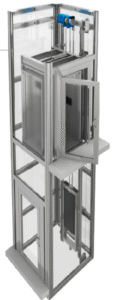

What “compact” really means

A compact lift is designed to deliver full-floor access with a tight footprint and minimal structural changes. That does not mean cramped. It means a smart balance between car size, shaft thickness, door width, pit depth and headroom.

In most New Zealand homes, a footprint from about 1.3 to 1.6 square metres can suit everyday needs. That typically starts around 1150 by 1150 mm for a compact traction model, up to around 1500 by 1500 mm for a standard lift that is wheelchair friendly.

One more dimension matters: the space outside the lift at each landing. A practical rule of thumb is to allow a clear 1400 to 1500 mm in front of the door wherever possible, so you can approach, turn, and exit without a shuffle.

A quick dimension reference

Every manufacturer has nuances. Still, the typical ranges below cover most compact residential options on the market in NZ. Treat them as planning guides rather than final cut sizes.

| Lift type | Typical internal car size (mm) | Typical shaft footprint (mm) | Pit depth | Headroom |

| Compact MRL Traction | 800×1000 to 900×1200 | 1150×1150 to 1300×1300 | 300 to 450 mm | 2600+ mm |

| Standard MRL Traction | 1000×1200 to 1100×1400 | 1500×1500 typical | 300 to 450 mm | 2600+ mm |

Even at a glance, you can see that pit depth and headroom are where the space benefits show up.

Shaft, pit and headroom explained

A lift shaft frames the car and houses guide rails, landing doors and safety systems. Thicker walls can improve acoustic separation and fire performance, but they add to the overall footprint. In timber-framed homes, a shaft built in 90 to 140 mm framing with plasterboard linings is common. In masonry or steel, wall thickness can be slimmer for the same stiffness.

The pit is a shallow recess below the lowest floor that ensures smooth levelling and space for safety gear. In compact home lifts, this depth is kept to an absolute minimum—often just a shallow recess in the slab rather than the deep excavation required by older commercial systems. Headroom is the clear height above the top landing. More headroom generally means more choice of doors and a nicer ride, but many compact platforms are engineered for low headroom ceilings found in existing houses.

How to read your plan for a realistic footprint

Start with what your household needs, then size the shaft. A family with an ageing parent or a wheelchair user will choose a larger car and a wider door. A couple in a narrow townhouse might prioritise slender plan dimensions.

After you mark out the car size on the floor, add wall thickness and at least 50 mm of service clearance. Then test door swing or sliding door width. Review landing space so you can approach from the preferred direction without a tight turn. This simple check helps you find the sweet spot before you get into the details.

Minimums that still feel generous

A popular compact platform lift will often use a car around 1000 by 1250 mm with a door clear opening near 900 mm. That is a comfortable size for a person with a walker, and workable for many wheelchairs. It lines up nicely with typical New Zealand hallway widths and ensures groceries, laundry baskets and luggage do not feel like a juggling act.

If you live in a tight terraced home, Canny’s Compact Series maximizes internal space without the noise or speed limitations of older platform lifts. A shaft size of around 1200 by 1200 mm is often the perfect balance.

Where a compact lift fits best

Site selection is half the job. The most space-efficient installs piggyback on existing voids or stacked cupboards, or tuck neatly into corners that do not carry the home’s structural loads. An external tower can also make sense when you want zero disruption to interiors.

These spots usually shine:

- Stair voids or return landings

- Stacked wardrobes between floors

- Garage to hallway connections

- Corner of a living room aligned with an upstairs corridor

A good designer will also look at plumbing and power runs, ceiling joists, and the most direct path for the cab and rails. Minimal rerouting equals minimal cost.

Retrofitting vs new build

New builds give you more freedom to place and proportion the lift. You can thicken walls for acoustic separation, integrate shaft cladding and structure cleanly, and choose door widths that suit the path of travel. You also get to coordinate with your truss design to preserve headroom with low roof pitches.

Retrofits call for a sharper pencil. You are weaving a precise rectangle through existing structure, often across two or three floors with varying ceiling heights. That is where compact technology earns its keep: low pits, low headroom, and machine-roomless designs cut through many obstacles. When in doubt, plan an early invasive check to find beams, ducts and hidden surprises.

Doors, approach and circulation

Door choice changes your space envelope. Sliding doors save clearance in tight corridors and are quiet in operation, but they add to shaft thickness and cost. Swing doors take less hardware but need approach space. For most homes, a clear door width near 900 mm is a smart target.

Landing circulation is just as important as the lift itself. If you can, allow:

- Clear 1400 to 1500 mm in front of the door

- Level, slip-resistant floor finishes

- Lighting at both landings that avoids glare

Those small touches make daily use effortless.

Noise, airflow and services

Compact lifts can be very quiet. Positioning still matters. Separating the shaft from bedrooms with a robe, linen cupboard or insulation layer makes night-time trips whisper-soft. If your chosen system uses a small hydraulic or control cabinet, a nearby cupboard keeps it tidy and accessible.

For airflow, make sure the shaft has the ventilation specified by the manufacturer. Most residential systems need only passive vents. Electrical supply is usually a standard single-phase feed with a dedicated circuit, although some larger platforms and speeds may require three-phase.

Standards, consent and safety in New Zealand

Residential lifts in New Zealand are consented building work. Your project will be designed to meet the NZ Building Code and the applicable lift standard for the chosen system, with producer statements and commissioning records provided on completion. Expect checks against structure, access, safety, fire separation around the shaft, electrical work, and the clearances in the manufacturer’s manual.

Practical safety features are built in. Over-speed protection, door interlocks, emergency lowering, battery backup for lighting and communication, and obstruction sensors are common across quality models. Ask to see the test and certification regime that applies to your chosen lift.

How Canny approaches compact spaces

Canny Residential Elevators combines world-class engineering with local know-how to fit lifts into New Zealand homes without drama. With products installed in a wide range of dwelling types and a support network across the country, the process gets handled end to end.

Our team plans for both the numbers and the lived experience: stepping in, reaching the controls, turning a mobility device, and stopping flush with a timber or tiled floor. Because that is what you notice every day.

After a site conversation, you can expect:

- Measured footprint advice: options from about 1.0 to 1.6 m², matched to your plan and use case

- Pit and headroom guidance: whether to form a pit, use a low ramp, or select a zero-pit model

- Consent-ready documentation: drawings, specifications and performance statements for council

- NZ-wide installation and aftercare: trained local installers and stocked parts

World-class in design, local in delivery.

The power of a good survey

A measured survey sets the tone. Before you lock in cabinetry or stair framing, confirm:

- Beam and joist directions

- Services that cross the alignment

- Finished floor levels at each landing

- Door approach widths and clear turning spaces

This small step can save painful changes later.

Choosing the right type for your space

Two questions help narrow the field. How small must the footprint be to protect your layout? How smooth and quiet do you want the ride to feel? Once you answer those, the choice tends to fall into place.

- Compact Series (Traction): Ideal for tighter spaces, offering a smooth ride with a footprint starting near 1.2m square.

- Standard Series (Belt/Rope Traction): The best choice for full wheelchair accessibility and larger capacity where space allows.

- Premium Custom: For unique architectural requirements or specific finishes.

There is no wrong answer, only a best fit for your home and your priorities.

Budgeting the space, not just the cost

When you are comparing quotes, check more than the price. The smallest nominal footprint can be undone by landing clearances or an awkward door swing. Look at the whole envelope: shaft, door, landing, and the route between them.

A well-chosen compact lift will often free up space somewhere else. If you no longer need a stacked storage cupboard, that space can go back into a wider hallway or a more generous bathroom.

Case sizes that work in practice

Here are three footprints that consistently fit New Zealand homes while keeping things comfortable.

- About 1150mm x 1150mm: fits Canny’s Compact Series. Best suited to two people or a standing rider with light items, fitting neatly into a stair void.

- About 1100 by 1250 mm: a sweet spot for compact platforms in a timber shaft, comfortable for a person with a walker or a slim wheelchair.

- About 1200 by 1400 mm: the go-to for a wheelchair-friendly car with a 900 mm door, while still fitting neatly in stacked cupboards.

If you are at the design stage, sketch each rectangle on the plan and trace the path of travel. It quickly reveals the best location.

Designed for Kiwi homes, backed here when you need it

Canny’s residential range is proven internationally and supported locally. That combination matters when you want a compact footprint without compromises.

You get NZ-wide site consultations, installers trained to global standards, responsive servicing, and help with consent documentation. The hardware arrives with the safety features you expect and the paperwork councils require.

Next steps and a site check

If you have a plan set, mark out your candidate footprint on both floors and note ceiling heights where the lift lands. Photos and rough dimensions are enough for an initial review. From there, a site consultation can confirm pit options, headroom, and the best door orientation for your layout.

Getting the space right first makes the rest straightforward. And that is how a compact home lift feels like it was always part of the house.